Some Ideas on Best Dust Extractors You Need To Know

Some Known Details About Best Dust Extractors

Table of ContentsA Biased View of Best Dust Extractors5 Simple Techniques For Best Dust ExtractorsLittle Known Facts About Best Dust Extractors.An Unbiased View of Best Dust ExtractorsThe Only Guide for Best Dust ExtractorsMore About Best Dust ExtractorsThe Main Principles Of Best Dust Extractors

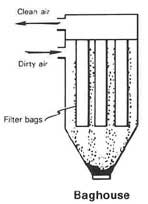

The best way to discuss what this indicates is to go on a scenic tour of the course that air follows through the dust collection system. Filthy air including particles of dirt enters the enthusiast via the ductwork.Because of this, this maintains the dirt from striking the filters at complete rate. After that the air enters what we call the unclean air plenum. This simply suggests the side of the collection agency where the air is unclean. At the end of this room, accumulated dirt goes down out right into a drum or hopper.

In the CMAXX, these hang up and down from the tube sheet, which is the metal sheet separating the dirty and also tidy air spaces. This makes the spaces that the air must go through smaller sized.

Get This Report about Best Dust Extractors

Gaskets at the top of each filter seal it to the tube sheet to keep dust from creeping via. Due to the fact that the pulse of compressed air goes in the reverse instructions of the normal airflow, we call it a reverse pulse-jet collection agency.

The dust drops out of the enthusiast and also the filters are ready to collect more dirt. A pulse-jet enthusiast is a really reliable type of industrial dirt collection system.

Typically a timer controls the diaphragm shutoffs. To make the cleaning extra efficient, the pulses can also be controlled by differential stress sensing units. Differential stress sensing units check out the air stress on the filthy air and clean air sides of the filters. The dirtier the filters are, the even more resistance they have to air experiencing them.

The 5-Minute Rule for Best Dust Extractors

Utilizing differential stress sensors makes a pulse-jet dust collector much more efficient because it minimizes using compressed air. It also aids the cartridge filters last much longer, due to the fact that the pulses of pressed air cause damage on them. Pulse-jet dust collection systems are reliable as a result of this filter cleansing.

By making filters last much longer, a pulse-jet collector is the most cost-efficient shop dirt collection system. Check out offline cartridge filter cleansing. Cartridge enthusiasts have the filters in either a horizontal or upright arrangement. In straight dust collection system style, the filters lay on their sides and are piled on top of each various other.

In a horizontal pulse-jet dust collector, the pulse cleansing triggers dirt to be blown off the filters. Nonetheless, because they're on top of each other, the dirt from the leading filters drops on top of the others. In a vertical pulse-jet collector, the dirt that pulses off of the filters goes down straight down right into the hopper.

Getting The Best Dust Extractors To Work

When contrasting biscuits vs dowels the top consideration is usually set you back. Yet woodworkers understand joint stamina, rate of configuration and alignment simplicity are vital considerations. Discover what joint is best for your projects in this overview.

If you specialize in metalworking, you currently recognize the relevance of appropriate dust collection. Not just can the steel contaminants released throughout use a sander pollute the air as well as unclean up your store, however they likewise have the prospective to trigger hazardous thermal occasions that can hurt workers and equipment.

These devices gather steel grindings and store them in a secure control space. Nonetheless, to ensure that your dust collection process is as efficient and also secure as possible, you'll need to comprehend the finest methods to run and also preserve read the article these important devices. Which's where we are available in. At Timesavers, we generate the very best woodworking and also metalworking ending up machines in the industry.

The Facts About Best Dust Extractors Revealed

Since you have a strong understanding of the advantages of damp dirt collectors, allow's dive a little bit deeper into exactly how these devices are utilized and also maintained. To start, operators will connect their commercial grinding maker to the collection agency via ductwork. These pipelines will transfer the airalong with any airborne dustinto the wet dust collection agency, pushing them both straight into the water storage tank.

After manufacturing ends, operators will certainly utilize an inside story to by hand pull debris up as well as out of the water storage tank, leaving it planned for the next run. Beyond these straightforward procedure actions, there are 2 vital aspects that enable wet dirt enthusiasts to operate appropriately. Best Dust Extractors. CFM (cubic feet per minute) determines the volume of air being moved, and static stress (Inches of Water) is the pressure of the air being relocated.

Have any added questions concerning dust collectors or steel completing in basic? You can likewise call us if you would certainly like to find out even more concerning our dirt collection equipments and how they can enhance the efficacy of your metalworking projects.

Things about Best Dust Extractors

Dust is a problem in any interior area. Many dust is additionally a flammable threat that require unique handling of the dirt.

NFPA 68 has because 2007 required all dirt to be evaluated to identify the explosiveness of the dirt. If the dust is not eruptive then the controls as stated above are not called for on dust collectors, and also on dust enthusiasts under 8 cubic feet of the filthy side of the enclosure are excluded.

In 2015 2021 NFPA 652 mandated all companies with dirt collection systems to provide a Dirt Threats Analysis DHA. This is a complete evaluation that includes the dirt test and also certain risks evaluation for that plant and operation. Generally done by a signed up engineer as well as can cost from $6000 to $20,000.

Best Dust Extractors - Truths

That is why AAir Purification Solutions styles, constructs, songs, and preserves high-grade commercial dirt collection systems for usage in a variety of industrial rooms. Yet exactly how does an industrial dust collection system work? For a beginning, it is essential to note that there are different kinds of dirt collection systems.

Different kinds of filters as well as various degrees as well as plans of air blood circulation i loved this or suction power are made use of to attain this. Generally, the dust from the treated air will be caught or come by the filter as the air enters into call with it. The dirt will certainly after that come under a sediment catcher or it will be mechanically scrubbed, cleaned, drunk, or pressed right into the debris collection area.

Then the over at this website air comes into contact with a collection of angled items of steel called baffles which slow down the air down to prevent the dirt from hitting the filters at a speed that would certainly damage the filters. The air is after that relocated into the plenum, which is another word for the debris collection agency discussed over.